N'etiti ndị na-abụghị siliceous oxides, alumina nwere ezi n'ibu Njirimara, elu okpomọkụ na-eguzogide na corrosion eguzogide, mgbe mesoporous alumina (MA) nwere mgbanwe pore size, nnukwu kpọmkwem n'elu ebe, nnukwu pore olu na ala mmepụta na-eri, nke a na-eji ọtụtụ ebe na catalysis, achịkwa ọgwụ ntọhapụ, adsorption na ndị ọzọ ubi, dị ka cracking, hydrocracking na hydrodesulfurization nke ụlọ ọrụ alumina na-ejikarị eme ihe na petrole. ga-emetụta kpọmkwem ọrụ nke alumina, ndụ ọrụ na selectivity nke catalyst. Dịka ọmụmaatụ, n'ime usoro ịsachacha ụgbọala, ihe ndị na-emetọ ihe ndị a na-etinye na mmanụ mmanụ ga-emepụta coke, nke ga-eduga na nkwụsị nke pores nke na-eme ka ọkpụkpụ, si otú ahụ na-ebelata ọrụ nke onye na-emepụta ihe. Enwere ike iji Surfactant mee ka nhazi nke ihe na-ebu alumina mepụta MA.Mmelite arụmọrụ catalytic ya.

MA nwere mmetụta mgbochi, na ọla ndị na-arụ ọrụ na-agbanyụọ ka mbelata okpomọkụ dị elu. Na mgbakwunye, mgbe calcination na-ekpo ọkụ dị elu, usoro mesoporous na-adaba, ọkpụkpụ MA dị na ọnọdụ amorphous, na acidity elu enweghị ike izute ihe ọ chọrọ n'ọhịa nke ịrụ ọrụ. A na-achọkarị ọgwụgwọ mgbanwe iji melite ọrụ catalytic, nkwụsi ike nke mesoporous, nkwụsi ike nke elu na elu acidity nke MA. n'ime ọkpụkpụ.

Nhazi eletrọn pụrụ iche nke ihe ndị na-adịghị ahụkebe ụwa na-eme ka ogige ya nwee ngwa anya pụrụ iche, eletriki na magnetik, a na-ejikwa ya na ihe catalytic, ihe fotoelectric, ihe adsorption na ihe ndọta. Obere ụwa gbanwetụrụ mesoporous ihe nwere ike ịgbanwe acid (alkali) onwunwe, dịkwuo oxygen ohere, na synthesize metal nanocrystalline catalyst na edo dispersion na mụ nanometer scale.Appropriate porous ihe na obere earths nwere ike melite elu dispersion nke metal nanocrystals na kwụsie ike na carbon deposition eguzogide nke catalysts. N'ime akwụkwọ a, a ga-ewebata mgbanwe ụwa na-adịghị ahụkebe na ịrụ ọrụ nke MA iji melite arụmọrụ catalytic, nkwụsi ike ọkụ, ikike nchekwa oxygen, mpaghara elu akọwapụtara na nhazi pore.

1 MA nkwadebe

1.1 nkwadebe nke alumina ebu

Usoro nkwadebe nke onye na-ebu alumina na-ekpebi nkesa ihe owuwu ya, na ụzọ nkwadebe ya na-agụnye usoro mmiri mmiri pseudo-boehmite (PB) na usoro sol-gel. Pseudoboehmite (PB) bụ nke mbụ Calvet tụpụtara ya, na H + kwalitere peptization iji nweta γ-AlOOH colloidal PB nwere mmiri interlayer, bụ nke a na-eme ka mmiri na-ekpo ọkụ na mmiri na-ekpo ọkụ na oke okpomọkụ iji mepụta alumina. Dị ka ihe dị iche iche dị iche iche si dị, a na-ekewakarị ya n'ime usoro mmiri ozuzo, usoro carbonization na usoro hydrolysis alcoholaluminium. A na-emetụta kristal colloidal solubility nke PB, na-eme ka ọ dịkwuo mma na mmụba nke crystallinity, ma na-emetụtakwa usoro nhazi usoro.

A na-akwadokarị PB site na usoro mmiri ozuzo. A na-agbakwunye Alkali n'ime ngwọta aluminate ma ọ bụ tinye acid n'ime ngwọta aluminate ma mee ka ọ nweta alumina hydrated (mmiri alkali), ma ọ bụ tinye acid n'ime mmiri ozuzo iji nweta alumina monohydrate, nke a na-asacha, nke a mịrị amị na calcined iji nweta PB. Usoro mmiri ozuzo dị mfe iji rụọ ọrụ na ọnụ ala dị ala, nke a na-ejikarị eme ihe na mmepụta mmepụta ihe, ma ọ na-emetụta ọtụtụ ihe (ngwọta pH, ntinye uche, okpomọkụ, wdg) .Na ọnọdụ ahụ maka ịnweta urughuru na mma dispersibility siri ike. Na usoro carbonization, Al (OH) 3 nwetara site na mmeghachi omume nke CO2 na NaAlO2, na PB nwere ike nweta mgbe ịka nká. Usoro a nwere uru nke ọrụ dị mfe, àgwà ngwaahịa dị elu, enweghị mmetọ na ọnụ ala dị ala, ma nwee ike ịkwadebe alumina na-arụ ọrụ catalytic dị elu, nkwụsị nke corrosion magburu onwe ya na ebe dị elu nke dị elu nke nwere obere ego na ntinye ego dị elu. A na-ejikarị usoro aluminom alkoxide hydrolysis kwadebe PB dị ọcha. Aluminom alkoxide na-hydrolyzed na-etolite aluminum oxide monohydrate, na mgbe ahụ na-emeso iji nweta elu-ọcha PB, nke nwere ezi crystallinity, edo urughuru size, lekwasị pore size nkesa na elu iguzosi ike n'ezi nke spherical ahụ. Otú ọ dị, usoro a dị mgbagwoju anya, ọ na-esikwa ike ịgbake n'ihi iji ụfọdụ ihe mgbaze organic na-egbu egbu.

Tụkwasị na nke ahụ, a na-ejikarị salts inorganic ma ọ bụ ngwakọta organic nke ọla eme ihe maka ịkwadebe alumina precursors site na usoro sol-gel, a na-agbakwunye mmiri dị ọcha ma ọ bụ ihe ndị na-edozi ahụ iji kwadebe ihe ngwọta maka ịmepụta sol, nke a na-agbaze, nke a mịrị amị na ṅara n'ọkụ. Ka ọ dị ugbu a, usoro nkwadebe nke alumina ka na-eme ka ọ dịkwuo mma na ndabere nke usoro mmiri mmiri PB, na usoro carbonization aghọwo isi usoro maka mmepụta alumina mmepụta ihe n'ihi na akụ na ụba ya na nchebe gburugburu ebe obibi.

1.2 MA nkwadebe

Alumina na-emekarị enweghị ike imezu ihe ndị a chọrọ, ya mere ọ dị mkpa iji kwadebe MA dị elu. Ụzọ njikọ ahụ na-agụnyekarị: usoro nkedo nano na carbon ebu dị ka template siri ike; Synthesis nke SDA: Usoro nhazi onwe onye na-ebute evaporation (EISA) na ọnụnọ nke ndebiri dị nro dị ka SDA na ndị ọzọ cationic, anionic ma ọ bụ nonionic surfactants.

1.2.1 Usoro EISA

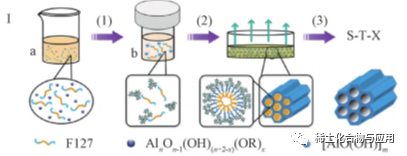

A na-eji template dị nro mee ihe na ọnọdụ acidic, nke na-ezere usoro mgbagwoju anya na nke na-ewe oge nke usoro akpụkpọ anụ siri ike ma nwee ike ịghọta mgbanwe mgbanwe nke oghere na-aga n'ihu. Nkwadebe nke MA site n'aka EISA adọtala nlebara anya nke ukwuu n'ihi ịdị mfe ya na mmụgharị ya. Enwere ike ịkwadebe ihe owuwu mesoporous dị iche iche. The pore size nke MA nwere ike gbanwee site n'ịgbanwe hydrophobic yinye ogologo surfactant ma ọ bụ na-edozi molar ruru nke hydrolysis catalyst ka aluminum precursor na solution.Ya mere, EISA, nke a makwaara dị ka otu nzọụkwụ njikọ na mgbanwe sol-gel usoro nke elu elu ebe MA na iwu mesoporous alumina (OMA), e tinyewo n'ọrụ dị iche iche soft templates, dị ka 1 F. wdg EISA nwere ike dochie ngalaba-mgbakọ usoro nke organoaluminom precursors, dị ka aluminum alkoxides na surfactant ndebiri, aluminom isopropoxide na P123, n'ihi na-enye mesoporous material.The ịga nke ọma mmepe nke EISA usoro chọrọ kpomkwem ukpụhọde nke hydrolysis na condensation kinetics nweta kwụsiri ike sol na ekwe ka mmepe nke surfac misophase.

N'ime usoro EISA, iji ihe mgbaze na-abụghị mmiri (dị ka ethanol) na ihe ndị na-emepụta ihe na-emepụta ihe nwere ike ime ka hydrolysis na condensation ọnụego nke organoaluminum precursors na-eme ka a na-ejikọta onwe ya nke ihe OMA, dị ka Al (OR) 3 na aluminum isopropoxide. Otú ọ dị, n'ime ihe mgbaze na-adịghị agbanwe agbanwe, ndebiri surfactant na-atụfukarị hydrophilicity/hydrophobicity ha. Na mgbakwunye, n'ihi igbu oge nke hydrolysis na polycondensation, ngwaahịa etiti nwere otu hydrophobic, nke na-eme ka o sie ike ịmekọrịta na template surfactant. Naanị mgbe ntinye nke surfactant na ogo nke hydrolysis na polycondensation nke aluminom na-eji nwayọọ nwayọọ na-abawanye na usoro nke evaporation ihe mgbaze nwere ike ịme onwe ya nke template na aluminum. Ya mere, ọtụtụ parameters na-emetụta ọnọdụ evaporation nke ihe mgbaze na hydrolysis na condensation mmeghachi omume nke precursors, dị ka okpomọkụ, ikwu iru mmiri, catalyst, mgbaze evaporation ọnụego, wdg, ga-emetụta ikpeazụ nzukọ Ọdịdị. Dị ka e gosiri na fig. 1, Ihe OMA nwere nkwụsi ike dị elu yana arụmọrụ catalytic dị elu sitere na solvothermal na-enyere aka evaporation na-ebute onwe ya (SA-EISA). solvothermal ọgwụgwọ kwalitere zuru ezu hydrolysis nke aluminom precursors na-etolite obere-sized ụyọkọ aluminum hydroxyl otu, nke enhances mmekọrịta dị n'etiti surfactants na aluminum. Abụọ akụkụ hexagonal mesophase e guzobere na EISA usoro na calcined na 400 ℃ na-emepụta OMA ihe. N'ime usoro EISA nke ọdịnala, usoro evaporation na-esonyere ya na hydrolysis nke organoaluminum precursor, ya mere ọnọdụ evaporation nwere mmetụta dị mkpa na mmeghachi omume na nhazi ikpeazụ nke OMA. Usoro ọgwụgwọ solvothermal na-akwalite hydrolysis zuru oke nke aluminom precursor ma na-emepụta akụkụ aluminom hydroxyl clustered akụkụ. Tụnyere MA nke a kwadebere site na usoro EISA ọdịnala, OMA nke usoro SA-EISA akwadoro nwere oke pore dị elu, mpaghara elu ka mma yana nkwụsi ike ka mma. N'ọdịnihu, enwere ike iji usoro EISA jikwaa nnukwu oghere MA nwere ọnụego ntụgharị dị elu yana nhọrọ dị oke mma na-ejighi onye na-ere ahịa.

Ihe eserese 1 na-agbapụta usoro SA-EISA maka ijikọ ihe OMA

1.2.2 usoro ndị ọzọ

Nkwadebe MA na-emekọrịta ihe na-achọ njikwa ziri ezi nke usoro njikọ iji nweta nhazi nke mesoporous doro anya, na mwepụ nke ihe ndebiri bụkwa ihe ịma aka, nke na-eme ka usoro nhazi ahụ sie ike. Ka ọ dị ugbu a, ọtụtụ akwụkwọ akọpụtala njikọ nke MA nwere ndebiri dị iche iche. N'ime afọ ndị na-adịbeghị anya, nchọpụta ahụ lekwasịrị anya na njikọ nke MA na glucose, sucrose na starch dị ka ndebiri site na aluminum isopropoxide na ngwọta mmiri. A ga-enwetakwa MA CTAB site na ngbanwe ozugbo nke PB dị ka isi iyi aluminum. MA dị iche iche structural Njirimara, ntụgharị Al2O3) -1, Al2O3) -2 na al2o3Na nwere ezi thermal kwụsie ike. Mgbakwunye nke surfactant anaghị agbanwe usoro kristal dị n'ime ya nke PB, kama ọ na-agbanwe ọnọdụ stacking nke ahụ. Na mgbakwunye, e guzobere Al2O3-3 site na adhesion nke nanoparticles kwụsie ike site organic mgbaze PEG ma ọ bụ aggregation gburugburu PEG. Agbanyeghị, oke nkesa nke Al2O3-1 dị warara. Tụkwasị na nke ahụ, a kwadebere ihe ndị na-eme ka palladium dabeere na synthetic MA dị ka onye na-ebu ya. Na mmeghachi omume combustion methane, ihe na-akwado nke Al2O3-3 gosipụtara arụmọrụ catalytic dị mma.

Maka oge mbụ, MA nwere nkesa nha nha dị warara dị warara kwadebere site na iji ọnụ ala na aluminom bara ụba na aluminum black slag ABD. Usoro mmepụta na-agụnye usoro mmịpụta na obere okpomọkụ na nrụgide nkịtị. Ihe siri ike fọdụrụ na usoro mmịpụta agaghị emetọ gburugburu ebe obibi, enwere ike ikpokọta ya na obere ihe ize ndụ ma ọ bụ jiri ya mee ihe dị ka ihe nkpuchi ma ọ bụ nchịkọta na ngwa ngwa. The kpọmkwem elu ebe synthesized MA bụ 123 ~ 162m2 / g, The pore nkesa bụ warara, ọnụ ọgụgụ kasị elu radius bụ 5.3nm, na porosity bụ 0.37 cm3 / g. Ihe ahụ nwere nha nano na nha kristal dị ihe dịka 11nm. Njikọ steeti siri ike bụ usoro ọhụrụ iji mepụta MA, nke enwere ike iji mepụta ihe na-anabata redio maka ojiji ụlọ ọgwụ. Aluminom chloride, ammonium carbonate na glucose akụrụngwa na-agwakọta na a molar ratio nke 1: 1.5: 1.5, na MA na-synthesized site ọhụrụ siri ike-ala mechanochemical mmeghachi omume.Site na-etinye uche131I na thermal batrị akụrụngwa, ngụkọta mkpụrụ nke131I mgbe ịta ahụhụ bụ 90%, na nwetara131I a / TB ngwọta nwere 1. N'ịghọta iji nnukwu dose131I[NaI] capsules maka ọgwụgwọ ọrịa cancer gị.

N'ịchịkọta, n'ọdịnihu, a nwekwara ike ịmepụta obere ihe ndebiri molekụla iji wuo ihe owuwu pore dị iche iche, na-edozi nhazi nke ọma, morphology na n'elu chemical Njirimara nke ihe, na ịmepụta nnukwu elu na iwu wormhole MA. Nyochaa ndebiri dị ọnụ ala na isi mmalite aluminom, kwalite usoro njikọ, dokwuo anya usoro njikọ ma duzie usoro ahụ.

Usoro mgbanwe nke 2 MA

Ụzọ nke ekesa ihe ndị na-arụ ọrụ n'otu n'otu na onye na-ebu MA gụnyere impregnation, in-situ synthe-sis, mmiri ozuzo, mgbanwe ion, ngwakọta igwe na agbaze, n'ime nke abụọ mbụ bụ nke a na-ejikarị eme ihe.

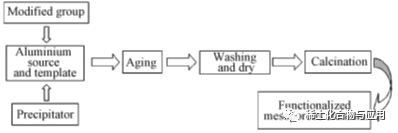

2.1 usoro njikọ n'ime ọnọdụ

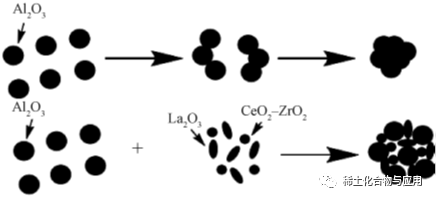

A na-agbakwunye otu ndị a na-eji na-arụ ọrụ na-arụ ọrụ na usoro nke ịkwadebe MA iji gbanwee ma mee ka ọkpụkpụ ọkpụkpụ nke ihe ahụ dịkwuo mma ma melite arụmọrụ catalytic. E gosipụtara usoro ahụ na eserese 2. Liu et al. synthesized Ni/Mo-Al2O3in situ na P123 dị ka template. Ma Ni na Mo gbasasịa na ọwa MA nyere iwu, na-emebighị usoro mesoporous nke MA, na arụmọrụ catalytic ka emelitere nke ọma. Ịnabata usoro uto n'ime ọnọdụ na gamma-al2o3substrate arụpụtara, Tụnyere γ-Al2O3, MnO2-Al2O3 nwere mpaghara elu BET buru ibu na oke pore, ma nwee usoro mesoporous bimodal nwere nkesa pore dị warara. MnO2-Al2O3 nwere ọnụego mgbasa ozi ngwa ngwa na arụmọrụ dị elu maka F-, ma nwee nnukwu ngwa pH (pH = 4 ~ 10), nke dabara maka ọnọdụ ngwa ngwa ụlọ ọrụ bara uru. Arụmọrụ imegharịgharị nke MnO2-Al2O3 dị mma karịa nke γ-Al2O.Structural kwụsie ike kwesịrị ka emeziwanye ya. N'ịchịkọta, MA gbanwetụrụ ihe enwetara site na in-site njikọ nwere ezigbo nhazi usoro, mmekọrịta siri ike n'etiti otu na ndị na-ebu alumina, nchikota siri ike, ibu ihe buru ibu, na ọ dịghị mfe ime ka mwụda nke ihe ndị na-arụ ọrụ na usoro mmeghachi omume catalytic, na ọrụ catalytic na-abawanye nke ọma.

Fig. 2 Nkwadebe nke na-arụ ọrụ MA site n'ime ebe obibi

2.2 usoro impregnation

Na-emikpu MA a kwadebere n'ime ìgwè a gbanwere, na ịnweta ihe MA gbanwere mgbe ọgwụgwọ gasịrị, iji ghọta mmetụta nke catalysis, adsorption na ihe ndị yiri ya. Cai et al. kwadebere MA sitere na P123 site na usoro sol-gel, wee tinye ya na ethanol na ngwọta tetraethylenepentamine iji nweta amino gbanwetụrụ MA ihe na arụmọrụ adsorption siri ike. Na mgbakwunye, Belkacemi et al. tinye na ZnCl2solution site n'otu usoro ahụ iji nweta iwu zinc doped gbanwetụrụ MA material.The kpọmkwem n'elu ebe na pore olu bụ 394m2 / g na 0.55 cm3 / g, karị. E jiri ya tụnyere usoro nhazi nke in-situ, usoro impregnation nwere mgbasa ozi ka mma, usoro mesoporous kwụsiri ike na arụmọrụ adsorption dị mma, mana ike mmekọrịta dị n'etiti ihe ndị na-arụ ọrụ na ndị na-ebu alumina adịghị ike, ọrụ catalytic na-adịkwa mfe site na mpụga ihe.

3 ọganihu ọrụ

Ngwakọta nke ụwa na-adịghị ahụkebe MA nwere ihe pụrụ iche bụ mmepe mmepe n'ọdịnihu. Ka ọ dị ugbu a, e nwere ọtụtụ ụzọ synthesis. Usoro usoro na-emetụta arụmọrụ MA. Enwere ike idozi mpaghara elu ahụ akọwapụtara, olu pore na dayameta pore nke MA site na ụdị ndebiri na ihe mejupụtara aluminom. Okpomọkụ calcination na ndebiri polymer na-emetụta mpaghara elu nke akọwapụtara na oke pore nke MA. Suzuki na Yamauchi chọpụtara na calcination okpomọkụ e ụba si 500 ℃ ka 900 ℃. The oghere nwere ike ụba na elu ebe nwere ike belata. Tụkwasị na nke ahụ, ọgwụgwọ mgbanwe ụwa na-adịghị ahụkebe na-eme ka ọrụ ahụ dịkwuo mma, nkwụsi ike nke elu, nkwụsi ike nhazi na elu acidity nke MA ihe na usoro catalytic, na izute mmepe nke MA functionalization.

3.1 Defluorination Adsorbent

Fluorine dị na mmiri ọṅụṅụ na China na-emerụ ahụ nke ukwuu. Na mgbakwunye, mmụba nke ọdịnaya fluorine na ngwọta zinc sulfate nke ụlọ ọrụ ga-eduga na corrosion nke efere electrode, mmebi nke gburugburu ebe ọrụ, mbelata nke zinc eletriki na mbelata nke mmiri a na-emegharịgharị na sistemu acid na usoro electrolysis nke mmiri ọkụ akwa akwa na-ekpo ọkụ gas. Ka ọ dị ugbu a, usoro mgbasa ozi bụ ihe kachasị mma n'etiti ụzọ ndị a na-emekarị nke mmiri mmiri mmiri. Otú ọ dị, e nwere ụfọdụ adịghị ike, dị ka ike mgbasa ozi na-adịghị mma, pH dị warara dị nso, mmetọ nke abụọ na ihe ndị ọzọ. A na-eji carbon arụ ọrụ, amorphous alumina, alumina na-arụ ọrụ na ihe ndị ọzọ na-eme ka a na-emepụta mmiri, ma ọnụ ahịa adsorbents dị elu, na ikike adsorption nke F-na ngwọta na-anọpụ iche ma ọ bụ nnukwu ntinye uche dị ala. ikike nke fluoride, na naanị na pH <6 nwere ike inwe ezigbo fluoride adsorption performance.MA adọtala uche zuru oke na njikwa mmetọ gburugburu ebe obibi n'ihi nnukwu ebe elu ya dị kpọmkwem, mmetụta nke pore pụrụ iche, arụmọrụ acid-base, thermal and mechanical kwụsie ike. Kundu et al. MA kwadoro ya na ikike mgbasa ozi fluorine kacha nke 62.5 mg / g. The fluorine adsorption ikike nke MA na-enwe mmetụta dị ukwuu site na njirimara nhazi ya, dị ka ebe a kapịrị ọnụ, akụkụ ndị na-arụ ọrụ elu, nha pore na mkpokọta pore size.Ndozi nke nhazi na ịrụ ọrụ nke MA bụ ụzọ dị mkpa iji melite arụmọrụ mgbasa ozi ya.

N'ihi acid siri ike nke La na isi ike nke fluorine, enwere njikọ siri ike n'etiti La na fluorine ion. N'ime afọ ndị na-adịbeghị anya, ụfọdụ nchọpụta achọpụtala na La dị ka onye na-agbanwe agbanwe nwere ike imeziwanye ikike mgbasa ozi nke fluoride. Otú ọ dị, n'ihi nkwụsi ike dị ala nke ndị adsorbents ụwa na-adịghị ahụkebe, a na-abanye n'ime ala ndị na-adịghị ahụkebe na ngwọta, na-ebute mmetọ mmiri nke abụọ na imerụ ahụ ike mmadụ. N'aka nke ọzọ, nnukwu ntinye nke aluminom na gburugburu mmiri bụ otu n'ime nsị na-emerụ ahụ ike mmadụ. Ya mere, ọ dị mkpa iji kwadebe ụdị adsorbent ihe mejupụtara ya na nkwụsi ike dị mma na enweghị nkwụsịtụ ma ọ bụ obere leaching nke ihe ndị ọzọ na usoro iwepụ fluorine. MA gbanwere site na La na Ce kwadoro site na impregnation usoro (La/MA na Ce/MA). A na-ebugharị obere oxides ụwa nke ọma n'elu MA maka oge mbụ, nke nwere arụmọrụ defluorination dị elu. Isi usoro nke iwepụ fluorine bụ adsorption electrostatic na adsorption kemịkalụ, ihe na-adọrọ adọrọ nke elu elu na ụgwọ mgbanwe ligand na-ejikọta ya na hydroxyl elu, ìgwè ọrụ hydroxyl na adsorbent elu na-emepụta njikọ hydrogen na F-, ike mgbanwe nke Lasor F-, na-emeziwanye ikike nke Lasor. saịtị mgbasa ozi hydroxyl ọzọ, na ikike mgbasa ozi nke F dị n'usoro nke La/MA>Ce/MA>MA. Site na mmụba nke ntinye uche mbụ, ikike adsorption nke fluorine na-abawanye. Mmetụta mgbasa ozi kachasị mma mgbe pH bụ 5 ~ 9, na usoro mgbasa ozi nke fluorine kwekọrọ na Langmuir isothermal adsorption model. Na mgbakwunye, adịghị ọcha nke ion sulfate na alumina nwekwara ike imetụta ịdị mma nke ihe nlele. Ọ bụ ezie na a na-eme nchọpụta metụtara ya na alumina a na-adịghị ahụkebe nke ụwa, ọtụtụ n'ime nchọpụta ahụ na-elekwasị anya na usoro nke adsorbent, nke siri ike iji ya mee ihe n'ime ụlọ ọrụ mmepụta ihe. N'ọdịnihu, anyị nwere ike ịmụ usoro nkesa nke fluorine complex na zinc sulfate solution na àgwà ọpụpụ nke fluorine ion, nweta nke ọma, ọnụ ala na mmeghari ohuru nke fluorine ion sulfotelurgyment na zinc ion sulfometate ngwọta nke zinc ion sulfateurgynt. Sistemu, ma guzobe usoro njikwa usoro maka ịgwọ ngwọta fluorine dị elu dabere na ụwa na-adịghị ahụkebe MA nano adsorbent.

3.2 Ihe na-eme ihe

3.2.1 Mgbanwe akọrọ nke methane

Ụwa na-adịghị ahụkebe nwere ike ịhazigharị acidity (ihe ndabere) nke ihe ndị nwere porous, na-amụba ohere ikuku oxygen, na synthesize ihe na-akpali akpali na mgbasasa otu, ọnụ ọgụgụ nanometer na nkwụsi ike. A na-ejikarị ya akwado ọla ndị mara mma na ọla ngbanwe iji mee ka methanation nke CO2 kwụsị. Ugbu a, obere ụwa gbanwetụrụ mesoporous ihe na-emepe emepe kwupụta methane akọrọ reforming (MDR), photocatalytic mmebi nke VOCs na ọdụ gas purification.Compared na ndị mara mma ọla (dị ka Pd, Ru, Rh, wdg) na ndị ọzọ mgbanwe ọla (dị ka Co, Fe, wdg), Ni / Al2O3catalyst na-eji ya n'ụzọ zuru ezu na-arụ ọrụ dị elu maka nkwụsi ike na-arụ ọrụ maka nkwụsi ike ya dị elu maka ọrụ ya dị elu. methane. Agbanyeghị, mwepu na ntinye carbon nke Ni nanoparticles n'elu Ni/Al2O3 na-eduga n'ịkwụsị ngwa ngwa nke ihe mkpali. Ya mere, ọ dị mkpa ịgbakwunye accelerant, gbanwee ihe na-ebu ihe ma melite ụzọ nkwadebe iji melite ọrụ catalytic, nkwụsi ike na nkwụsị ọkụ. N'ozuzu, obere ụwa oxides ike ga-eji dị ka structural na eletrọnịkị na-akwalite na heterogeneous catalysts, na CeO2imelite mgbasa nke Ni na-agbanwe Njirimara nke dara Ni site ike metal nkwado mmekọrịta.

A na-eji MA eme ihe n'ọtụtụ ebe iji kwalite mgbasa nke ọla, ma na-enye mgbochi maka ọla ndị na-arụ ọrụ iji gbochie agglomeration ha. La2O3 nwere ikike nchekwa ikuku oxygen dị elu na-eme ka nkwụsị carbon dị na usoro ntụgharị, na La2O3 na-akwalite mgbasa nke Co na mesoporous alumina, nke nwere nnukwu ọrụ mgbanwe na resilience. La2O3promoter na-abawanye ọrụ MDR nke Co / MA catalyst, na Co3O4and CoAl2O4phases na-etolite n'elu ihe na-eme ka ọ dị elu. Otú ọ dị, La2O3 gbasasịrị nke ukwuu nwere obere mkpụrụ nke 8nm ~ 10nm. N'ime usoro MDR, mmekọrịta dị n'ime ọnọdụ dị n'etiti La2O3 na CO2 mere La2O2CO3mesophase, nke mere ka mkpochapụ CxHy dị irè n'elu ihe na-emepụta ihe. La2O3 na-akwalite mbelata hydrogen site n'inye njupụta elektrọn dị elu na ịkwalite ohere ikuku oxygen na 10% Co/MA. Mgbakwunye La2O3 na-ebelata ike mmalite pụtara ìhè nke oriri CH4. Ya mere, ọnụ ọgụgụ ntụgharị nke CH4 mụbara na 93.7% na 1073K K. Mgbakwunye nke La2O3 mere ka ọrụ catalytic dịkwuo mma, kwalitere mbelata H2, mụbaa ọnụ ọgụgụ nke saịtị Co0 na-arụ ọrụ, na-emepụta obere carbon na-echekwa ma mee ka ohere ikuku oxygen dị na 73.3%.

A kwadoro Ce na Pr na Ni/Al2O3catalyst site na usoro impregnation nha nha nha na Li Xiaofeng. Mgbe ịgbakwunye Ce na Pr, nhọrọ na H2 abawanyela yana nhọrọ na CO belatara. MDR meziri nke Pr nwere ikike catalytic magburu onwe ya, na nhọrọ na H2 abawanyela site na 64.5% ruo 75.6%, ebe nhọrọ na CO gbadara na 31.4% Peng Shujing et al. eji usoro sol-gel, Ce-modified MA kwadebere ya na aluminum isopropoxide, isopropanol solvent na cerium nitrate hexahydrate. Ebe a kapịrị ọnụ nke ngwaahịa ahụ mụbara ntakịrị. Mgbakwunye nke Ce belatara nchịkọta nke mkpịrịka nanoparticles dị ka mkpanaka n'elu MA. Ụfọdụ ìgwè hydroxyl dị n'elu γ- Al2O3 bụ ndị Ce ogige kpuchiri isi. A kwalitere nkwụsi ike nke okpomọkụ nke MA, ọ dịghịkwa mgbanwe mgbanwe kristal mere mgbe calcination na 1000 ℃ maka awa 10. Wang Baowei et al. akwadoro MA ihe CeO2-Al2O4by usoro nchikota. CeO2 nwere obere ọka cubic ka ekesara n'otu n'otu na alumina. Mgbe akwadochara Co na Mo na CeO2-Al2O4, mmekọrịta dị n'etiti alumina na akụrụngwa Co na Mo bụ nke CEO2 gbochiri nke ọma.

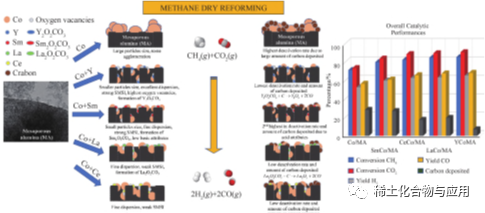

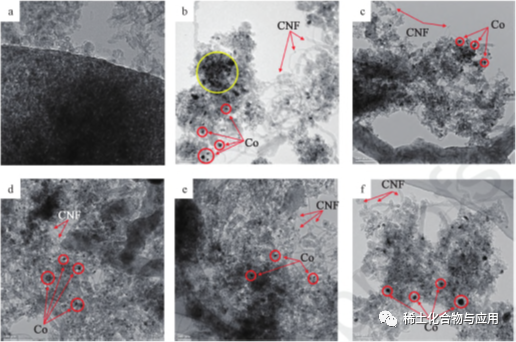

Ndị na-akwalite ụwa na-adịghị ahụkebe (La, Ce, y na Sm) jikọtara ya na Co/MA catalyst maka MDR, a na-egosikwa usoro a na fig. 3. ndị obere ụwa na-akwalite nwere ike melite mgbasa nke Co on MA ụgbọelu na-egbochi agglomeration nke co ahụ. The nta urughuru size, na ike Co-MA mmekọrịta, ike na catalytic na sintering ike na YCo / MA catalyst, na nti mmetụta nke ọtụtụ ndị na-akwalite na MDR ọrụ na carbon deposition.Fig. 4 bụ HRTEM iMAge mgbe ọgwụgwọ MDR gasịrị na 1023K, Co2: ch4: N2 = 1 ∶ 1 ∶ 3.1 maka awa 8. Co ahụ dị n'ụdị ntụpọ ojii, ebe ndị na-ebu MA dị n'ụdị isi awọ, nke dabere na ọdịiche nke njupụta elektrọn. na HRTEM oyiyi na 10% Co/MA (fig. 4b), agglomeration nke Co metal particles na-hụrụ na ma na-ebu ihe mgbakwunye nke obere ụwa nkwalite na-ebelata Co particles na 11.0nm ~ 12.5nm. YCo/MA nwere mmekọrịta Co-MA siri ike, yana arụmọrụ ya dị mma karịa ihe ndị ọzọ. na mgbakwunye, dị ka e gosiri na fig. 4b ruo 4f, a na-emepụta carbon nanowires oghere (CNF) na ihe ndị na-emepụta ihe, nke na-ejikọta ya na ikuku gas ma gbochie ihe na-eme ka ọ ghara imebi.

Fig. 3 Mmetụta nke mgbakwunye ụwa na-adịghị ahụkebe na akụrụngwa anụ ahụ na kemịkalụ yana arụmọrụ MDR catalytic nke Co/MA catalyst.

3.2.2 Deoxidation catalyst

Fe2O3/Meso-CeAl, ihe na-eme ka deoxidation nke dabeere na Ce-doped Fe, kwadoro site na oxidative dehydrogenation nke 1-butene na CO2as soft oxidant, na-eji na njikọ nke 1,3-butadiene (BD). Ce e ukwuu chụsasịrị na alumina matrix, na Fe2O3 / meso bụ ukwuu chụgaraFe2O3 / Meso-CeAl-100 catalyst bụghị nanị nwere ukwuu chụgara ígwè ụdị na ezi structural Njirimara, ma nwere ezi oxygen nchekwa ikike, n'ihi ya, ọ nwere ezi adsorption na ebighị ikike nke CO2. Dị ka e gosiri na Figure 5, TEM oyiyi na-egosi na Fe2O3 / Meso-CeAl-100 bụ regularIt na-egosi na worm-dị ka ọwa Ọdịdị nke MesoCeAl-100 bụ rụrụ na porous, nke bara uru na dispersion nke nọ n'ọrụ Efrata, mgbe ukwuu gbasasịrị Ce na-ọma doped na alumina matrix. Ihe mkpuchi ihe mkpuchi metal dị mma na-ezute ọkọlọtọ ụgbọ ala dị ala ewepụtala ihe owuwu pore, ezigbo nkwụsi ike hydrothermal na nnukwu nchekwa ikuku oxygen.

3.2.3 Na-eme ka ụgbọ ala

Pd-Rh na-akwado quaternary aluminum dabeere obere ụwa mgbagwoju AlCeZrTiOx na AlLaZrTiOx iji nweta ihe mkpuchi akpaaka akpaaka. Enwere ike iji mesoporous aluminum dabeere obere ụwa mgbagwoju anya Pd-Rh / ALC nke ọma dị ka ihe na-eme ka ọ dị ọcha na-ekpochapụ ụgbọ ala CNG na ịdịte aka dị mma, na ntughari arụmọrụ nke CH4, isi akụkụ nke CNG gas iyuzucha ụgbọ ala, dị elu dị ka 97.8%. Nabata a hydrotherMAl otu nzọụkwụ usoro iji kwadebe na obere ụwa ma mejupụtara ihe na-aghọta onwe-ngbakọta, nyere iwu mesoporous precursors na metastable steeti na elu aggregation e synthesized, na njikọ nke RE-Al kwekọrọ na nlereanya nke "mgbagwojuru ibu unit", si otú na-aghọta na-ọcha nke ụgbọala-agwụ ike-n'ịnyịnya post-mounted atọ.

Fig. 4 HRTEM onyonyo ma (a), Co/MA(b), LaCo/MA(c), CeCo/MA(d), YCo/MA(e) na SmCo/MA(f)

Fig. 5 onyonyo TEM (A) na ihe osise EDS (b,c) nke Fe2O3/Meso-CeAl-100

3.3 luminous arụmọrụ

Electrons nke ihe ndị na-adịghị ahụkebe ụwa na-enwe mmasị n'ụzọ dị mfe na mgbanwe n'etiti ọkwa ike dị iche iche ma na-ebunye ọkụ. A na-ejikarị ion ụwa na-adịghị ahụkebe eme ihe dị ka ndị na-arụ ọrụ iji kwadebe ihe ndị na-egbuke egbuke. Enwere ike ịkwanye ion ụwa na-adịghị ahụkebe n'elu aluminom phosphate oghere microspheres site na usoro nchikota na usoro mgbanwe ion, na ihe ndị na-egbuke egbuke AlPO4∶RE (La, Ce, Pr, Nd) nwere ike ịkwadebe. The luminescent wavelength dị nso ultraviolet region.MA na-mere n'ime mkpa fim ruru ya inertia, ala dielectric mgbe nile na ala conductivity, nke na-eme ka ọ na ọdabara eletriki na ngwa anya ngwaọrụ, mkpa fim, ihe mgbochi, sensọ, wdg Ọ nwekwara ike-eji maka mmetụta nzaghachi otu akụkụ photonic kristal, ike mkpuchi ọgbọ na mgbochi reflection. Ngwaọrụ ndị a na-ekpuchi ihe nkiri na ogologo ụzọ anya anya, n'ihi ya, ọ dị mkpa ijikwa index refractive na ọkpụrụkpụ. A na-agbasawanye ihe dị iche iche nke ihe nwere kemịkal dị iche iche dị n'elu, nke na-eme ka o kwe omume ịmepụta ihe mmetụta foton dị elu. Iwebata ihe nkiri MA na oxyhydroxide na nhazi nke ngwa anya na-egosi ikike dị ukwuu n'ihi na ntinye aka na-eme ka ọ dị ka nke silicon dioxide. Ma ihe ndị dị na kemịkal dị iche iche.

3.4 thermal kwụsie ike

Site na mmụba nke okpomọkụ, sintering na-emetụta mmetụta ojiji nke MA catalyst, na mpaghara elu ahụ akọwapụtara na-ebelata na γ-Al2O3in crystalline na-agbanwe n'ime δ na θ ka χ usoro. Ihe ndị dị ụkọ n'ụwa nwere ezigbo nkwụsi ike kemịkalụ yana nkwụsi ike ọkụ, ngbanwe dị elu, yana ngwa ngwa dị na ngwa ngwa dị ọnụ ala. Mgbakwunye nke obere ụwa ọcha nwere ike melite thermal kwụsie ike, elu okpomọkụ ọxịdashọn-eguzogide na n'ibu Njirimara nke ụgbọelu, na mezie elu acidity nke carrier.La na Ce bụ ndị kasị eji na-amụ mgbanwe ọcha. Lu Weiguang na ndị ọzọ chọpụtara na mgbakwunye nke ihe ndị na-adịghị ahụkebe nke ụwa na-egbochi oke mgbasa nke alumina ahụ, La na Ce chebere ìgwè hydroxyl n'elu alumina, na-egbochi sintering na mgbanwe nke oge, ma belata mmebi nke okpomọkụ dị elu na usoro mesoporous. Alumina a kwadebere ka nwere ebe elu dị elu na oke pore. Otú ọ dị, oke ma ọ bụ obere obere ihe ọkụkụ ụwa ga-ebelata nkwụsi ike nke alumina. Li Yanqiu et al. gbakwunyere 5% La2O3to γ-Al2O3, nke mere ka nkwụsi ike nke okpomọkụ dịkwuo mma ma mụbaa ụda pore na mpaghara elu nke alumina na-ebu. Dị ka a na-ahụ site na eserese 6, La2O3 gbakwunyere na γ-Al2O3, kwalite nkwụsi ike nke okpomọkụ nke ihe na-ebu ihe mejupụtara ụwa.

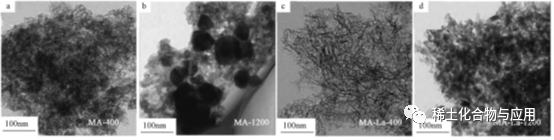

N'ime usoro nke doping nano-fibrous particles na La ka MA, BET n'elu ebe na pore olu nke MA-La dị elu karịa nke MA mgbe okpomọkụ ọgwụgwọ okpomọkụ na-abawanye, na doping na La nwere doro anya retarding mmetụta na sintering na elu okpomọkụ. dị ka e gosiri na fig. 7, na mmụba nke okpomọkụ, La na-egbochi mmeghachi omume nke uto ọka na mgbanwe oge, mgbe fig. 7a na 7c na-egosi nchikota nke nano-fibrous irighiri. na fig. 7b, dayameta nke nnukwu ihe na-emepụta site calcination na 1200 ℃ bụ banyere 100nm. Ọ akara ịrịba sintering nke MA. Na mgbakwunye, ma e jiri ya tụnyere MA-1200, MA-La-1200 anaghị ejikọta mgbe ọgwụgwọ okpomọkụ gasịrị. Na mgbakwunye na nke La, nano-fiber particles nwere mma sintering ike. ọbụlagodi na okpomọkụ calcination dị elu, doped La ka na-agbasasị nke ukwuu n'elu MA. Enwere ike iji La gbanwetụrụ MA dị ka onye na-ebu Pd catalyst na mmeghachi omume C3H8oxidation.

Fig. 6 Ọdịdị ihe nlereanya nke sintering alumina na-enweghị ụkọ ụwa ọcha

Ihe oyiyi 7 TEM oyiyi nke MA-400 (a), MA-1200 (b), MA-La-400 (c) na MA-La-1200 (d)

4 Nkwubi okwu

A na-ewebata ọganihu nke nkwadebe na ngwa arụ ọrụ nke ihe ndị na-adịghị ahụkebe ụwa gbanwere. A na-eji obere ụwa emezigharị MA eme ihe n'ọtụtụ ebe. Ọ bụ ezie na a na-eme ọtụtụ nyocha na ngwa catalytic, nkwụsi ike nke okpomọkụ na mgbasa ozi, ọtụtụ ihe nwere ọnụ ahịa dị elu, ego doping dị ala, usoro adịghị mma ma sie ike ịmepụta ụlọ ọrụ. A ghaghị ịrụ ọrụ ndị a n'ọdịnihu: kwalite nhazi na nhazi nke ụwa na-adịghị ahụkebe MA, họrọ usoro kwesịrị ekwesị, zute mmepe ọrụ; Mepụta usoro njikwa usoro dabere na usoro ọrụ iji belata ọnụ ahịa ma ghọta mmepụta mmepụta ihe; Iji bulie uru nke akụ ụwa na-adịghị ahụkebe nke China, anyị kwesịrị inyocha usoro nke mgbanwe ụwa na-adịghị ahụkebe MA, kwalite echiche na usoro ịkwadebe ụwa na-adịghị ahụkebe gbanwetụrụ MA.

Ọrụ ego: Shaanxi Science and Technology N'ozuzu Innovation Project (2011KTDZ01-04-01); Mpaghara Shaanxi 2019 Pụrụ Iche Nnyocha Sayensị Pụrụ Iche (19JK0490); Ọrụ nyocha sayensị pụrụ iche nke 2020 nke kọleji Huaqing, Mahadum Xi nke Architecture na Teknụzụ (20KY02)

Isi mmalite: Ụwa dị ụkọ

Oge nzipu: Jul-04-2022