Kedu mmetụta oxides ụwa na-adịghị ahụkebe na mkpuchi seramiiki?

A na-edepụta seramiki, ihe igwe na ihe polymer dị ka ihe atọ bụ isi siri ike. Seramiiki nwere ọtụtụ ihe magburu onwe ya, dị ka elu okpomọkụ nguzogide, corrosion iguzogide, eyi iguzogide, wdg, n'ihi na atomiki bonding mode nke seramiiki bụ ionic bond, covalent bond ma ọ bụ agwakọta ion-covalent bond na elu nkekọ ike. Ihe mkpuchi seramiiki nwere ike ịgbanwe ọdịdị, nhazi na arụmọrụ nke elu elu nke mkpụrụ ahụ, a na-akwado mkpuchi mkpuchi-substrate maka arụmọrụ ọhụrụ ya. Ọ nwere ike organically ikpokọta mbụ e ji mara mkpụrụ na e ji mara elu okpomọkụ na-eguzogide, elu eyi na-eguzogide na elu corrosion eguzogide nke seramiiki ihe, na-enye zuru play na keukwu uru nke abụọ di iche iche nke ihe, n'ihi ya, ọ na-ọtụtụ ebe na-eji ụgbọelu, ụgbọ elu, mba agbachitere, chemical ụlọ ọrụ na ndị ọzọ na ụlọ ọrụ.

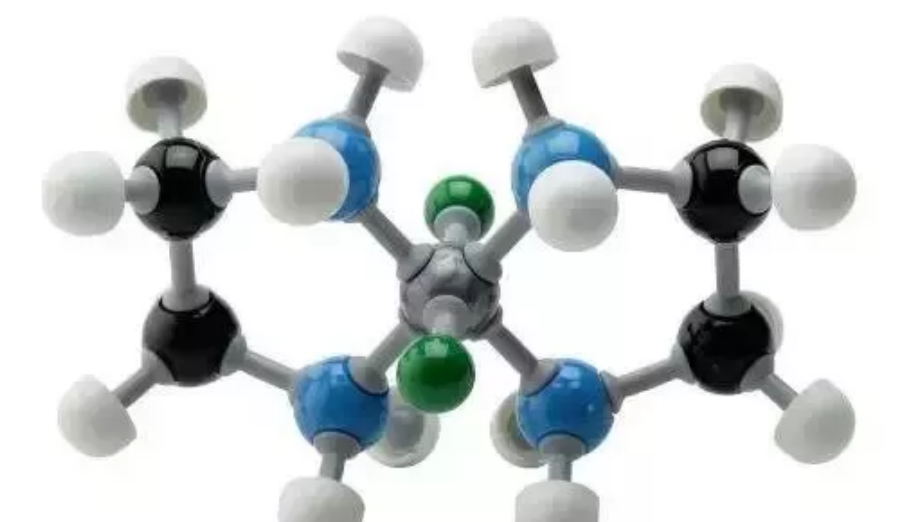

A na-akpọ ụwa na-adịghị ahụkebe "ụlọ akụ" nke ihe ọhụrụ, n'ihi nhazi eletrọnịkị 4f pụrụ iche na ihe anụ ahụ na kemịkal. Otú ọ dị, a na-ejikarị ọla ndị dị ọcha na-adịghị ahụkebe eme ihe ozugbo na nyocha, na ogige ụwa na-adịghị ahụkebe na-ejikarị eme ihe. Ogige ndị a na-ahụkarị bụ CeO2, La2O3, Y2O3, LaF3, CeF, CeS na obere ụwa ferrosilicon. Ihe ndị a na-adịghị ahụkebe ụwa nwere ike imeziwanye nhazi na njirimara nke ihe seramiiki na mkpuchi seramiiki.

Ana m etinye oxides ụwa na-adịghị ahụkebe na ihe seramiiki

Ịgbakwunye ihe ndị na-adịghị ahụkebe nke ụwa dị ka ihe nkwụsi ike na ịgbanye AIDS na seramiki dị iche iche nwere ike ibelata okpomọkụ na-ekpo ọkụ, melite ike na ike nke ụfọdụ seramiki nhazi, ma si otú ahụ belata ọnụ ahịa mmepụta. N'otu oge ahụ, ihe ndị na-adịghị ahụkebe ụwa na-arụkwa ọrụ dị oke mkpa na sensọ gas semiconductor, mgbasa ozi microwave, ceramics piezoelectric na ceramics ndị ọzọ na-arụ ọrụ. Nnyocha ahụ chọpụtara na, Ịgbakwunye abụọ ma ọ bụ karịa ụwa oxides na alumina ceramics ọnụ dị mma karịa ịgbakwunye otu oxide ụwa na-adịghị ahụkebe na seramiki alumina. Mgbe ule kachasị mma, Y2O3+CeO2 nwere mmetụta kachasị mma. Mgbe 0.2% Y2O3 + 0.2% CeO2 na-agbakwunyere na 1490 ℃, ndị ikwu njupụta nke sintered samples nwere ike iru 96.2%, nke karịrị njupụta nke samples ọ bụla obere ụwa oxide Y2O3 ma ọ bụ CeO2 naanị.

Mmetụta nke La2O3 + Y2O3, Sm2O3 + La2O3 n'ịkwalite sintering dị mma karịa nke ịgbakwunye naanị La2O3, na nkwụsi ike na-eyi ka o doro anya na ọ ka mma. Ọ na-egosikwa na ịgwakọta nke abụọ oxides ụwa na-adịghị ahụkebe abụghị ihe mgbakwunye dị mfe, ma enwere mmekọrịta dị n'etiti ha, nke bara uru karị maka nkwụsịtụ na ịrụ ọrụ nke ceramics alumina, ma ụkpụrụ ahụ ka ga-amụ.

Na mgbakwunye, achọpụtara na mgbakwunye na ngwakọta nke metal oxides na-adịghị ahụkebe dị ka ọrịa AIDS na-eme ka ọ dịkwuo mma nwere ike ime ka mbugharị nke ihe dị mma, kwalite nrịbama nke ceramik MgO ma melite njupụta. Otú ọ dị, mgbe ọdịnaya nke ngwakọta metal oxide karịrị 15%, ndị ikwu njupụta na-ebelata na oghere porosity na-abawanye.

Nke abụọ, mmetụta nke oxides ụwa na-adịghị ahụkebe na njirimara nke mkpuchi seramiiki

Nnyocha ndị dị adị na-egosi na ihe ndị dị n'ụwa na-adịghị ahụkebe nwere ike imezi nha ọka, mụbaa njupụta, melite microstructure ma mee ka interface ahụ dị ọcha. Ọ na-arụ ọrụ pụrụ iche n'ịkwalite ike, ike, ike siri ike, na-eyi nguzogide na mgbochi corrosion nke mkpuchi seramiiki, nke na-eme ka arụmọrụ nke mkpuchi seramiiki dịkwuo mma ruo n'ókè ụfọdụ ma gbasaa ngwa ngwa nke mkpuchi seramiiki.

1

Mmelite nke ihe eji arụ ọrụ nke mkpuchi seramiiki site na obere oxides ụwa

Oxides nke ụwa na-adịghị ahụkebe nwere ike imeziwanye ike ike, na-ehulata ike na ike njikọta nke mkpuchi seramiiki. Nsonaazụ nnwale na-egosi na enwere ike imeziwanye ike ike nke mkpuchi ahụ nke ọma site na iji Lao _ 2 dị ka mgbakwunye na ihe mgbakwunye na Al2O3 + 3% TiO _ 2, na ike njikọ ike nwere ike iru 27.36MPa mgbe ọnụọgụ nke Lao _ 2 bụ 6.0%. Na-agbakwụnye CeO2 na ọnụ ọgụgụ dị nta nke 3.0% na 6.0% n'ime ihe Cr2O3, ike ike nke mkpuchi mkpuchi dị n'etiti 18 ~ 25MPa, nke dị ukwuu karịa 12 ~ 16MPa mbụ, Otú ọ dị, mgbe ọdịnaya nke CeO2 bụ 9.0%, ike nkekọ ike na-ebelata na 12 ~ 15MPa.

2

Mmelite nke nguzogide ujo okpomọkụ nke mkpuchi seramiiki site na obere ala

Nnwale ujo na-eguzogide okpomọkụ bụ ule dị mkpa iji gosipụta nke ọma ike njikọ dị n'etiti mkpuchi na mkpụrụ na ndakọrịta nke ọnụọgụ mgbasawanye ọkụ n'etiti mkpuchi na mkpụrụ. Ọ na-egosipụta kpọmkwem ike nke mkpuchi iguzogide peeling mgbe okpomọkụ na-agbanwe ọzọ n'oge eji, na-egosipụtakwa ikike nke mkpuchi iguzogide n'ibu ujo ike ọgwụgwụ na bonding ike na mkpụrụ si side.Ya mere, ọ bụkwa isi ihe na-ekpebi àgwà nke seramiiki mkpuchi.

Nnyocha ahụ na-egosi na mgbakwunye nke 3.0% CeO2 nwere ike ibelata porosity na pore size na mkpuchi, ma belata nrụgide nrụgide na nsọtụ nke pores, si otú ahụ na-eme ka ihe mgbochi okpomọkụ nke mkpuchi Cr2O3 dịkwuo mma. Otú ọ dị, porosity nke Al2O3 seramiiki mkpuchi belatara, na bonding ike na thermal ujo ọdịda ndụ nke mkpuchi mụbara doro anya mgbe gbakwunyere LaO2. Mgbe ego mgbakwunye nke LaO2 bụ 6% (ọnụọgụ uka), Nguzogide ujo mkpuchi nke mkpuchi bụ ihe kacha mma, na ndụ ọdịda okpomọkụ nke okpomọkụ nwere ike iru ugboro 218, ebe ndụ mkpuchi okpomọkụ nke mkpuchi na-enweghị LaO2 bụ naanị ugboro 163.

3

Oxides ụwa na-adịghị ahụkebe na-emetụta nguzogide iyi nke mkpuchi

Okike ụwa na-adịghị ahụkebe eji emeziwanye nkwụsi ike nke mkpuchi seramiiki na-abụkarị CeO2 na La2O3. Ọdịdị ha nwere okirikiri hexagonal nwere ike igosi ọrụ mmanye mmanye dị mma ma na-ejigide akụrụngwa kemịkalụ kwụsiri ike na oke okpomoku, nke nwere ike melite nguzogide eyi nke ọma ma belata ọnụọgụ esemokwu.

Nnyocha ahụ na-egosi na ọnụọgụ esemokwu nke mkpuchi na ego kwesịrị ekwesị nke CeO2 dị ntakịrị ma kwụsie ike. A kọwapụtala na ịgbakwunye La2O3 na mkpuchi cermet nke nickel na-efesa plasma nwere ike belata nhụta esemokwu na ọnụọgụ mkpuchi, yana ọnụọgụ esemokwu kwụsiri ike na obere mgbanwe. Uwe akwa mkpuchi mkpuchi na-enweghị ụwa na-adịghị ahụkebe na-egosi njigide siri ike na mgbaji na-agbaji agbaji na spalling, Otú ọ dị, mkpuchi nke nwere ụwa na-adịghị ahụkebe na-egosi nrapanye na-adịghị ike n'elu elu eyi, ọ dịghịkwa ihe ịrịba ama nke nnukwu ebe na-agbaji agbaji. Microstructure nke mkpuchi mkpuchi ụwa na-adịghị ahụkebe na-adị obere ma na-agbakọ ọnụ, na pores na-ebelata, nke na-ebelata nkezi esemokwu ike nke ụmụ irighiri ihe na-akpata ma na-ebelata esemokwu na iyi Doping obere ụwa nwekwara ike ịbawanye anya ụgbọ elu kristal nke cermets, ọ na-eduga na mgbanwe nke ike mmekọrịta dị n'etiti ihu kristal abụọ ma belata ọnụ ọgụgụ esemokwu.

Nchịkọta:

Ọ bụ ezie na obere ụwa oxides mere oké rụzuru na ngwa nke seramiiki ihe na coatings, nke nwere ike n'ụzọ dị irè melite microstructure na n'ibu Njirimara nke seramiiki ihe na coatings, e nwere ka ọtụtụ ndị na-amaghị Njirimara, karịsịa na mbenata esemokwu na wear.How ime ka ike na-eyi iguzogide ihe na-akwado ha lubricating Njirimara aghọwo ihe dị mkpa ntụziaka kwesịrị nkwurịta okwu na ubi nke tribology.

Tel: +86-21-20970332Email:info@shxlchem.com

Oge nzipu: Jul-04-2022